Case Study Overview

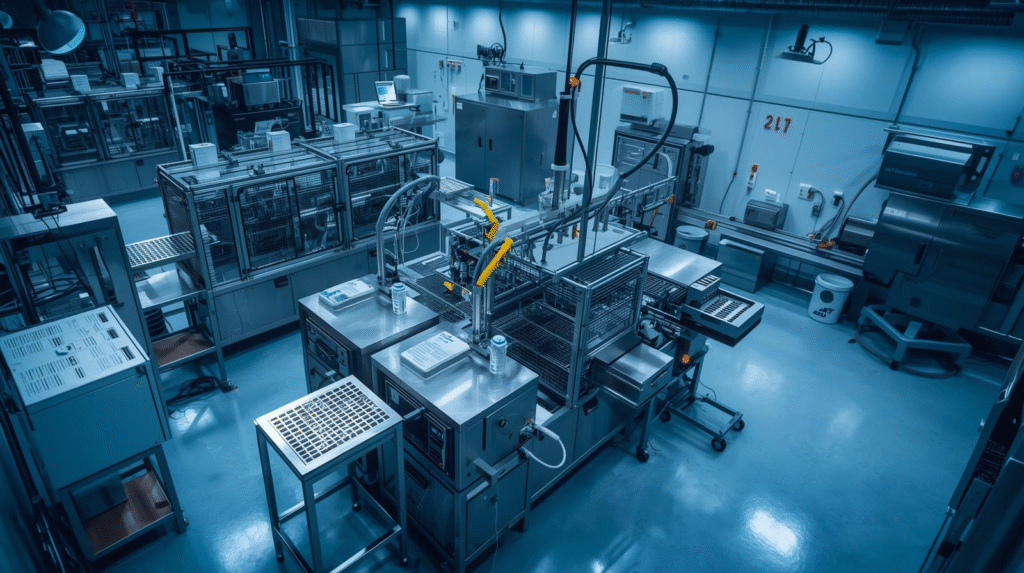

Sterility assurance remediation in sterile biologics manufacturing is one of the most critical challenges for vaccine and injectable drug producers. When aseptic operations fall short of Annex 1 requirements, the risks extend beyond compliance — threatening patient safety, regulatory approval, and supply continuity. This case study shows how GMP Bridge supported a DACH-based biologics manufacturer to redesign its Contamination Control Strategy (CCS), optimize Environmental Monitoring (EM), and strengthen Quality Oversight, ensuring sustainable compliance and restored client confidence.

The Challenge

A sterile biologics manufacturer in the DACH region faced significant sterility assurance risks after repeated client complaints and regulatory observations. The site’s aseptic operations were considered non-compliant, with gaps in oversight, contamination control, and environmental monitoring practices threatening supply continuity and regulatory trust.